Winkhaus infinityCoat : Enhanced surface finish

New standard coating for door locking solutions and window systems

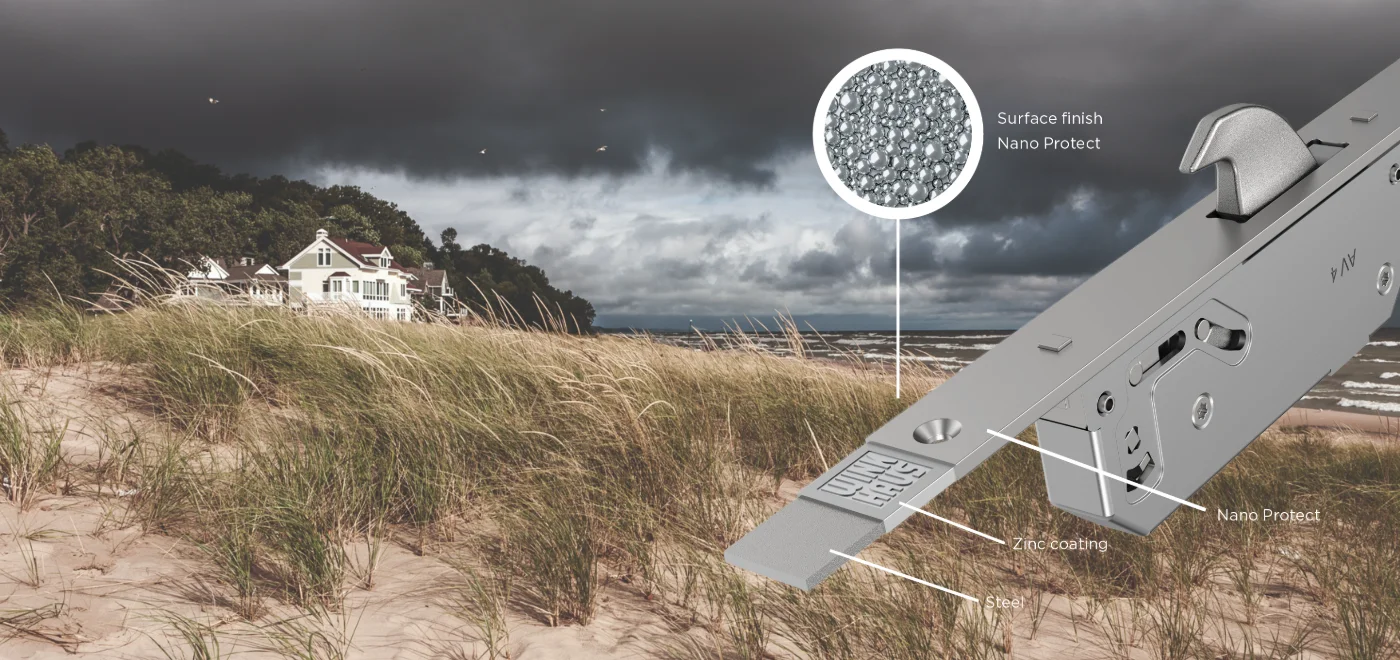

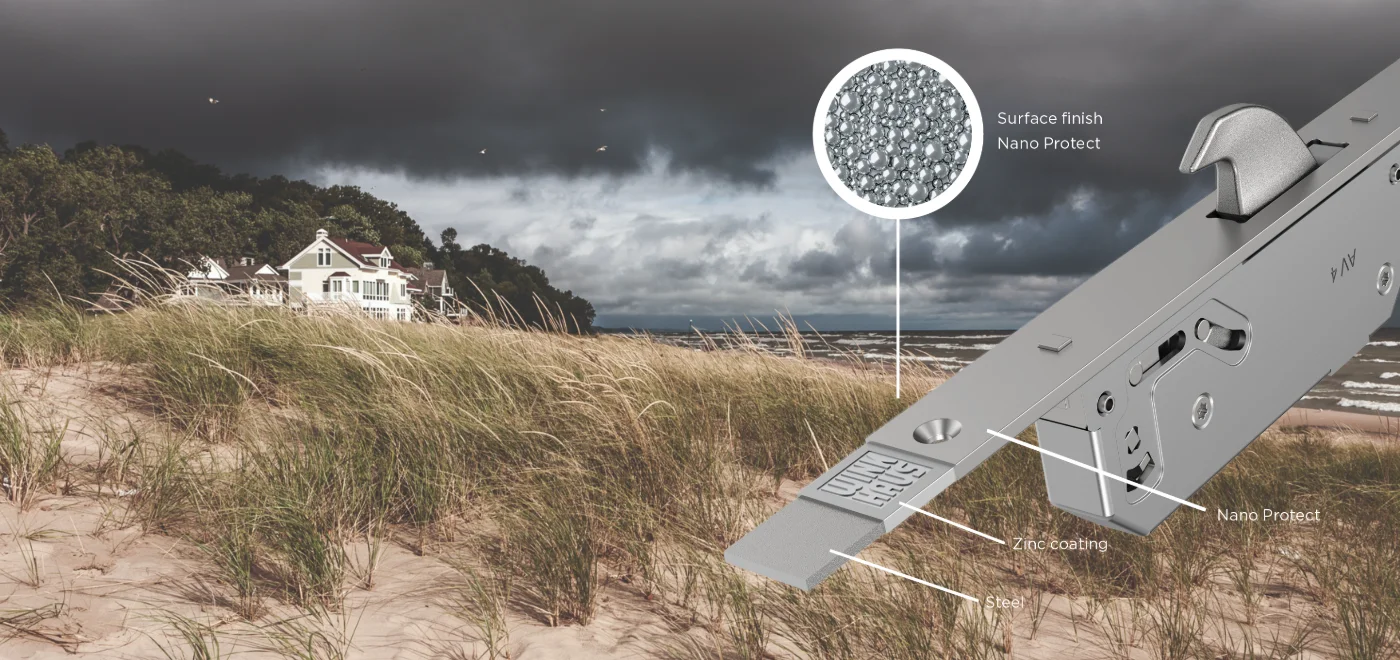

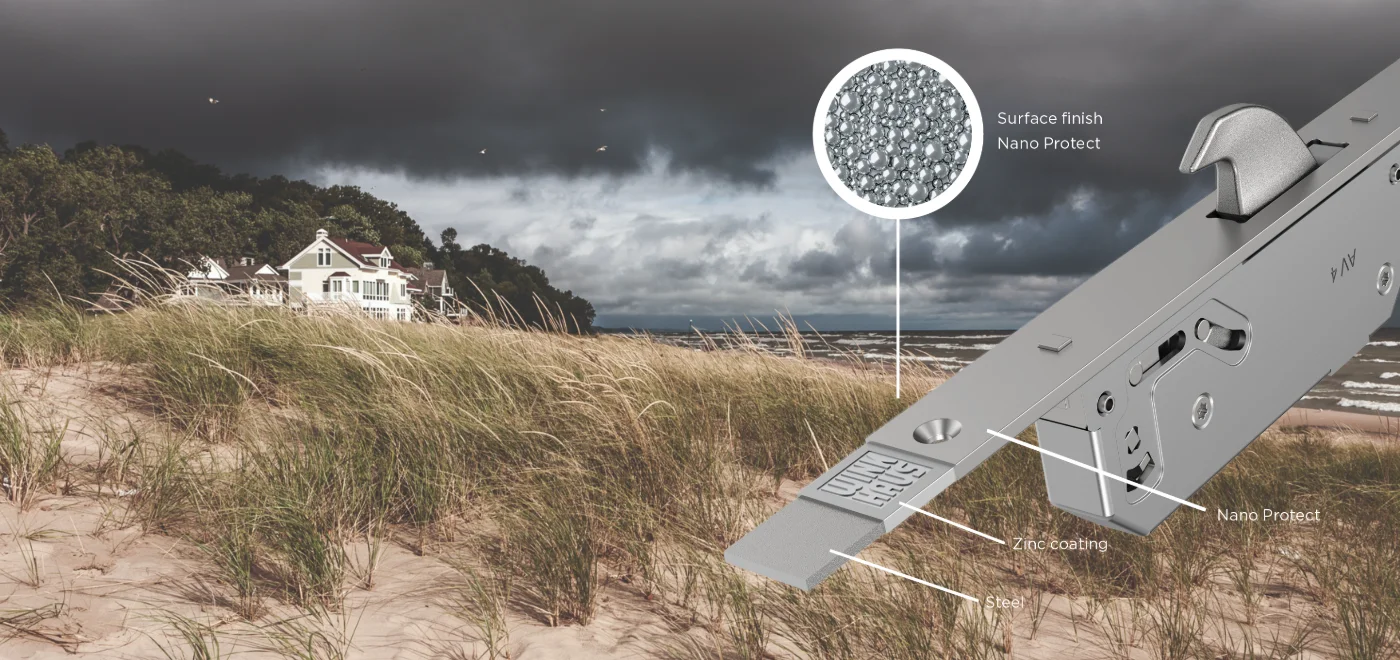

The British weather is famed for its variability, so it’s important to choose door and window locking solutions that are up to the task. Winkhaus door locking solutions and window systems are renowned for their reliability and longevity, which will be further enhanced with the introduction of our innovative infinityCoat. Winkhaus subjects its steel to a complex finishing process in its own electroplating facilities to ensure that the technology can withstand a wide range of attacks. The result is excellent corrosion resistance and an appealing finish that lasts for many decades.

Highest resistance class as standard

Winkhaus door and window solutions with infinityCoat have been tested to the requirements of EN 1670 corrosion protection class 5, which requires emersion in a salt water mist for 480 hours. Once the testing requirement was reached, testing continued with our infinityCoat achieving a 66% overrun above the class 5 requirement.

Scratch-resistant for everyday use

A remarkable feature of the infinityCoat is its self-regeneration ability: In the case of light scratches through daily use, the silicon dioxide particles contained in the coating layers can “migrate” to the affected area and seal them permanently. This makes Winkhaus door and window solutions exceptionally durable, maintaining the protective barrier for far longer.

In-house electroplating facility:

Quality and on-schedule production in our own hands Winkhaus is one of the few manufacturers to perform electroplating in its own plants. In-house technology development and expertise has many advantages: a high level of quality, reduced dependence on suppliers, quick reaction capability, responsible handling of coating materials and sustainable, resource-saving processes. To achieve this, Winkhaus has invested in state of-the-art technologies at its German manufacturing sites in Telgte and Meiningen. In house laboratories, treatment plants, and combined heat and power plants promote environmentally friendly and resource-saving operations. The waste heat from production is used to heat the electroplating plants. Independence from third-party coaters also enables us to react more quickly to customer requests and determine surface quality entirely on our own.

Precisely what you would expect as the standard coating on every Winkhaus door and window solution.

The innovative standard infinityCoat can successfully prevent corrosion on Winkhaus fittings. The surface even recovers from everyday wear and tear.

For more information, visit Products.